At Eagle Medical, we specialize in advanced bonding and fastening techniques for medical device manufacturing. Whether your assembly requires adhesives, mechanical interlocks, or hybrid fastening solutions, we determine the optimal method through rigorous drop, pull, and durability testing, all within our ISO-certified cleanroom environments.

Our team collaborates closely with yours to select the right bonding agents and fastening methods for your unique product, materials, and performance requirements. We help you define clear parameters, from mechanical properties to environmental exposure, ensuring reliable, biocompatible, and sterilization-ready bonds every time.

The bonding process can be achieved through surface absorption, chemical bonding, diffusion, electrostatic attraction or mechanical interlocking. Customer input on bonding agents and fasteners is crucial to correct selection, and Eagle works closely with customers to make sure details important to performance are captured.

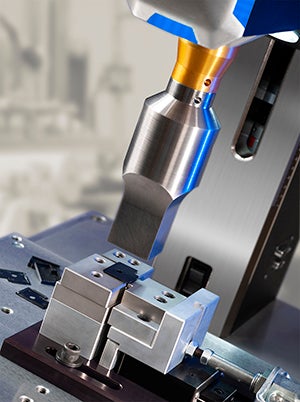

Surface Preparation Techniques: Grit blasting, etching, sonification, and other treatments prepare surfaces for maximum adhesion and long-term reliability.

Bonding Mechanisms: We support all major adhesion modes, including surface absorption, chemical bonding, diffusion, mechanical interlocking, and more.

Collaborative Selection: Your input is essential. We work with your engineers to establish performance targets for stress/strain tolerances, chemical interaction, sterilization compatibility, and environmental durability.