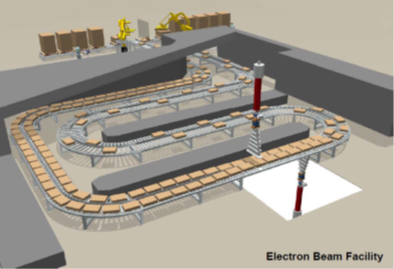

An electron beam is generated through the use of electromagnetic fields in a vacuum to gather and propel electrons to a very high speed. This beam is then quickly scanned up and down over a product as it is moved down a conveyor, resulting in a fully packaged and sterilized end-product.

As the high energy beam comes in contact with would-be contaminants, it ionizes and alters the structure of their DNA, eliminating their ability to function and reproduce.

This process can penetrate most types of low-density packaging and will leave no chemical residue or radiation behind. Though it is the fastest production method for high throughput device sterilization, it is limited by the density of the material that it can penetrate and the potential for material property changes caused by the induced static charge from the electron beam.

Eagle Medical works with Steri-Tek in Fremont, California to provide our customers with fast and reliable contract E-Beam sterilization in accordance with the ISO 11137 standard.