At Eagle Medical, our sterile pouch systems are engineered to provide high-performance protection, fast-cycle compatibility, and airtight compliance, especially for complex, sensitive, or mixed-format medical devices.

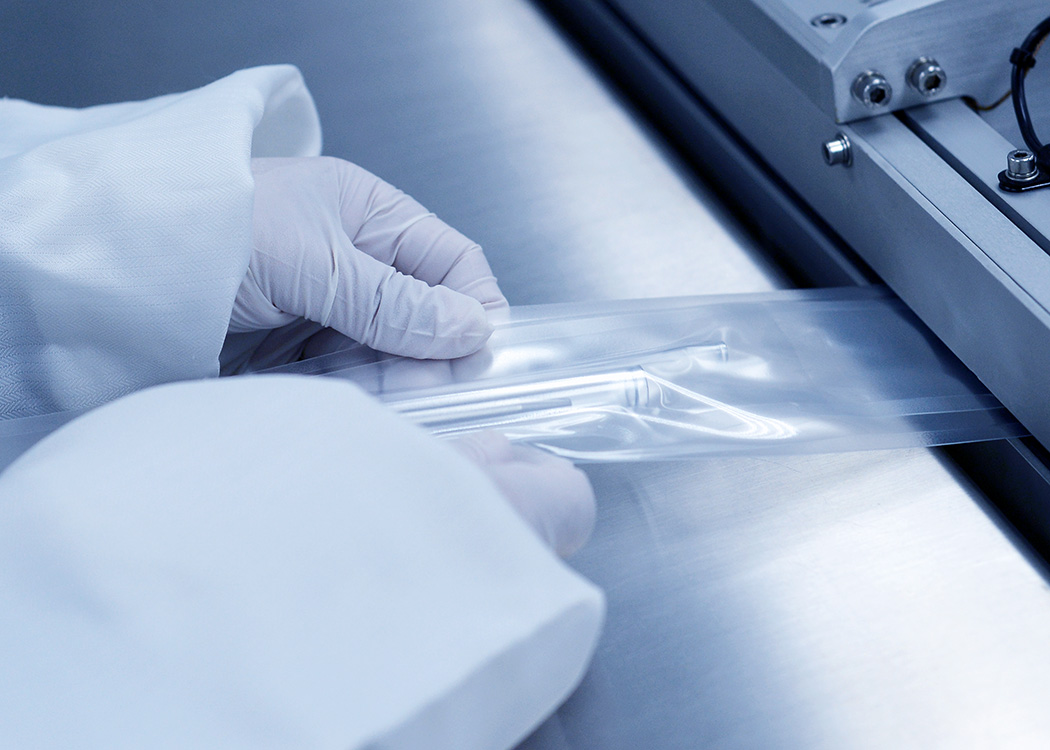

Using Tyvek®, multi-layer films, and advanced sealing technologies, we build pouch configurations that support your device’s unique geometry, sterilization pathway, and clinical use case. Whether you need validated single-barrier packaging or custom pouching within a kitted configuration, we’ll help you achieve it faster and with full documentation support.

We offer a wide variety of validated pouch formats and material combinations, tailored for your product’s performance, cost, and regulatory requirements:

All pouch solutions are assembled in our ISO Class 7 cleanrooms and are fully compatible with our VH₂O₂ and EtO sterilization services, ensuring end-to-end system integrity under one roof.

Every pouch system we produce is backed by a rigorous and traceable validation framework. Our services include:

If your product is still in development, we can help define the ideal packaging configuration in parallel with your sterilization and assembly pathways, streamlining verification and reducing design-phase risk.

We don’t just make pouches. We make systems that hold up in the real world. Our engineers help you account for:

And because our team works directly with sterilization, assembly, and packaging under one roof, we ensure your pouch performs not just in testing, but in practice.

Need more than just a prevalidated seal on a pouch? This is your solution! Readipouch consists of Pre-Configured, Pre-Structured, Pre-Validated (Pre-CSV) medical device packaging components. It is the only pre-validated sterile barrier solution, combining pre-configured secondary packaging.

Whether you need a scalable solution for high-throughput production or a specialized pouch for a mission-critical device, Eagle Medical delivers with speed, intelligence, and integrity.